Double Head Duplex Head Nails

Application

A double-ended nail is essentially a nail with two heads instead of one. One head is smaller than the other and is used to hold the material to be fastened, while the larger head is used to hold the nail in place. The double-ended design provides additional strength and stability, making it ideal for certain construction applications.

One of the most famous applications of studs is in the construction of wooden structures such as houses, fences and decks. Larger nail heads provide greater pullout resistance, which is useful when securing heavy objects. Since the wooden structure is exposed to the natural environment, the studs also have special corrosion and rust resistance, ensuring long-lasting stability and safety.

Duplex head nails have certain design elements that enhance their ease of use and installation. The smaller nail heads are often painted or colored, providing visual cues to aid in proper alignment and positioning. In addition, the smaller head is usually tapered or pointed for easier insertion into the material without the need for pre-drilling.

Feature

The key feature of duplex head nails is their versatility in industrial and manufacturing settings. Larger nail heads facilitate removal and replacement, which is important in the repair and maintenance of various industrial components. The strength and stability of studs also make them ideal for use on heavy machinery and equipment, providing extra support and safety.

The introduction of duplex head nails has revolutionized the way materials are fastened and fastened in construction, industrial and manufacturing environments. Its unique design and features provide additional strength and stability, making it ideal for heavy-duty applications. Furthermore, their versatility and ease of use make them a valuable asset in maintenance and repair work. As the industry continues to evolve, duplex head nails are clearly an innovation that is here to stay.

Material Constituents for Common Wire Nails

|

Sus |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

|

304 |

0.08 |

1.00 |

2.00 |

0.045 |

0.027 |

8.0-10.5 |

18.0-20.0 |

0.75 |

0.75 |

|

304Hc |

0.08 |

1.00 |

2.00 |

0.045 |

0.028 |

8.5-10.5 |

17.0-19.0 |

|

2.0-3.0 |

|

316 |

0.08 |

1.00 |

2.00 |

0.045 |

0.029 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

0.75 |

|

430 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

|

16.0-18.0 |

|

Wire Brands for Different Country

|

mm |

CN.W.G |

S.W.G |

B.W.G |

AS.W.G |

|

1G |

|

|

7.52 |

7.19 |

|

2G |

|

|

7.21 |

6.67 |

|

3G |

|

|

6.58 |

6.19 |

|

4G |

|

|

6.05 |

5.72 |

|

5G |

|

|

5.59 |

5.26 |

|

6G |

5.00 |

4.88 |

5.16 |

4.88 |

|

7G |

4.50 |

4.47 |

4.57 |

4.50 |

|

8G |

4.10 |

4.06 |

4.19 |

4.12 |

|

9G |

3.70 |

3.66 |

3.76 |

3.77 |

|

10G |

3.40 |

3.25 |

3.40 |

3.43 |

|

11G |

3.10 |

2.95 |

2.05 |

3.06 |

|

12G |

2.80 |

2.64 |

2.77 |

2.68 |

|

13G |

2.50 |

2.34 |

2.41 |

2.32 |

|

14G |

2.00 |

2.03 |

2.11 |

2.03 |

|

15G |

1.80 |

1.83 |

1.83 |

1.83 |

|

16G |

1.60 |

1.63 |

1.65 |

1.58 |

|

17G |

1.40 |

1.42 |

1.47 |

1.37 |

|

18G |

1.20 |

1.22 |

1.25 |

1.21 |

|

19G |

1.10 |

1.02 |

1.07 |

1.04 |

|

20G |

1.00 |

0.91 |

0.89 |

0.88 |

|

21G |

0.90 |

0.81 |

0.81 |

0.81 |

|

22G |

|

0.71 |

0.71 |

0.73 |

|

23G |

|

0.61 |

0.63 |

0.66 |

|

24G |

|

0.56 |

0.56 |

0.58 |

|

25G |

|

0.51 |

0.51 |

0.52 |

Custom Design Nails

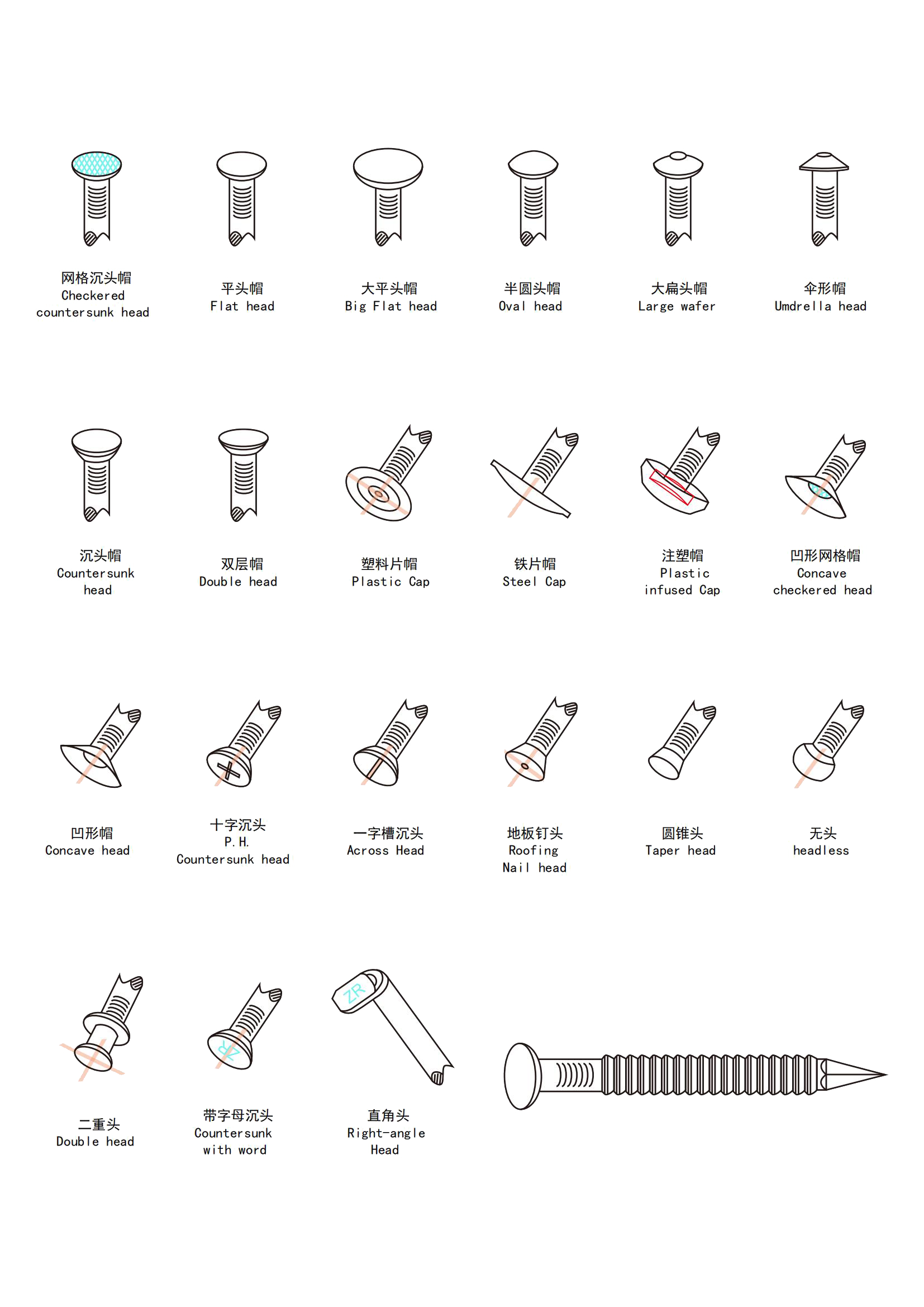

Type and Shape of Nails Head

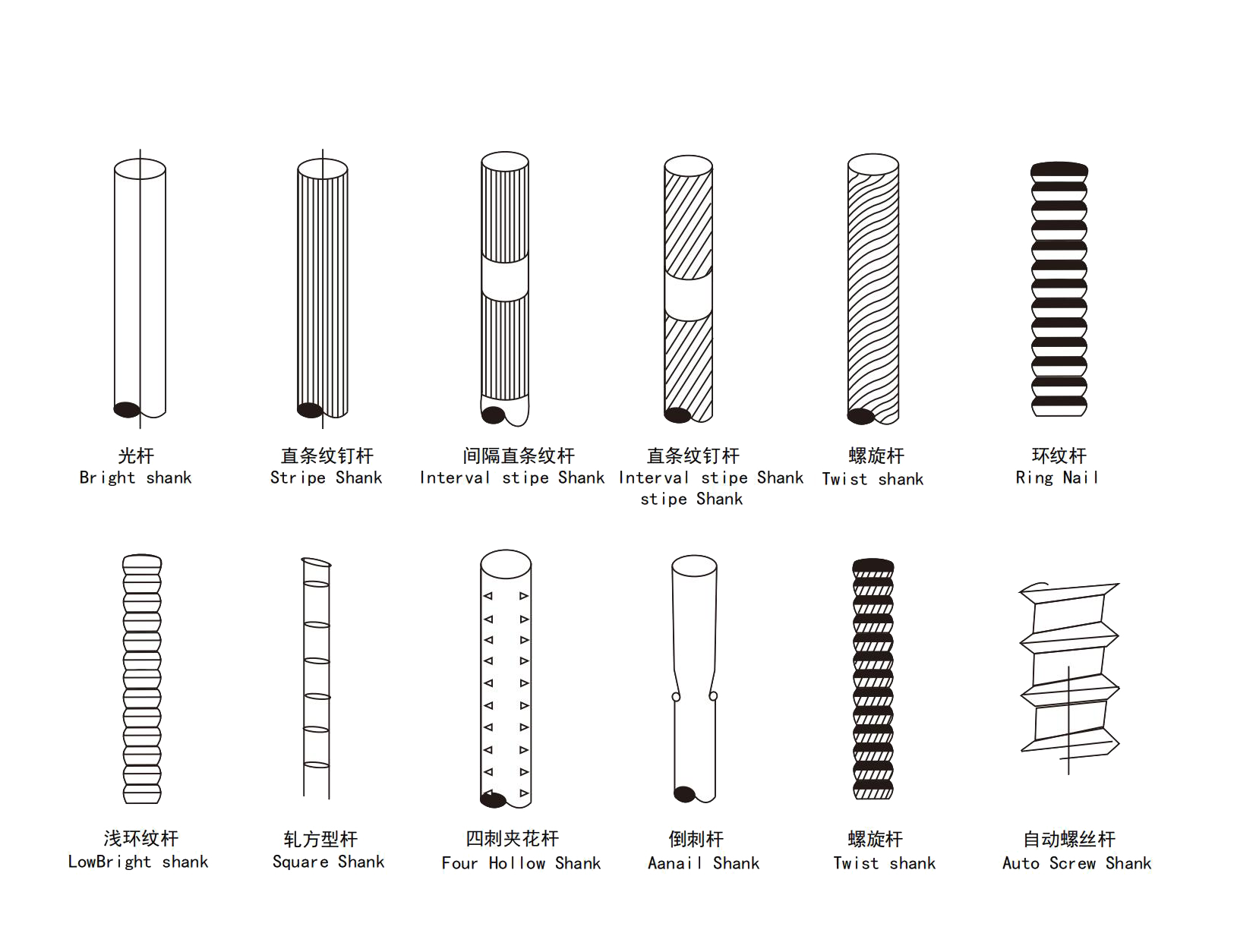

Type and Shape of Nails Shank

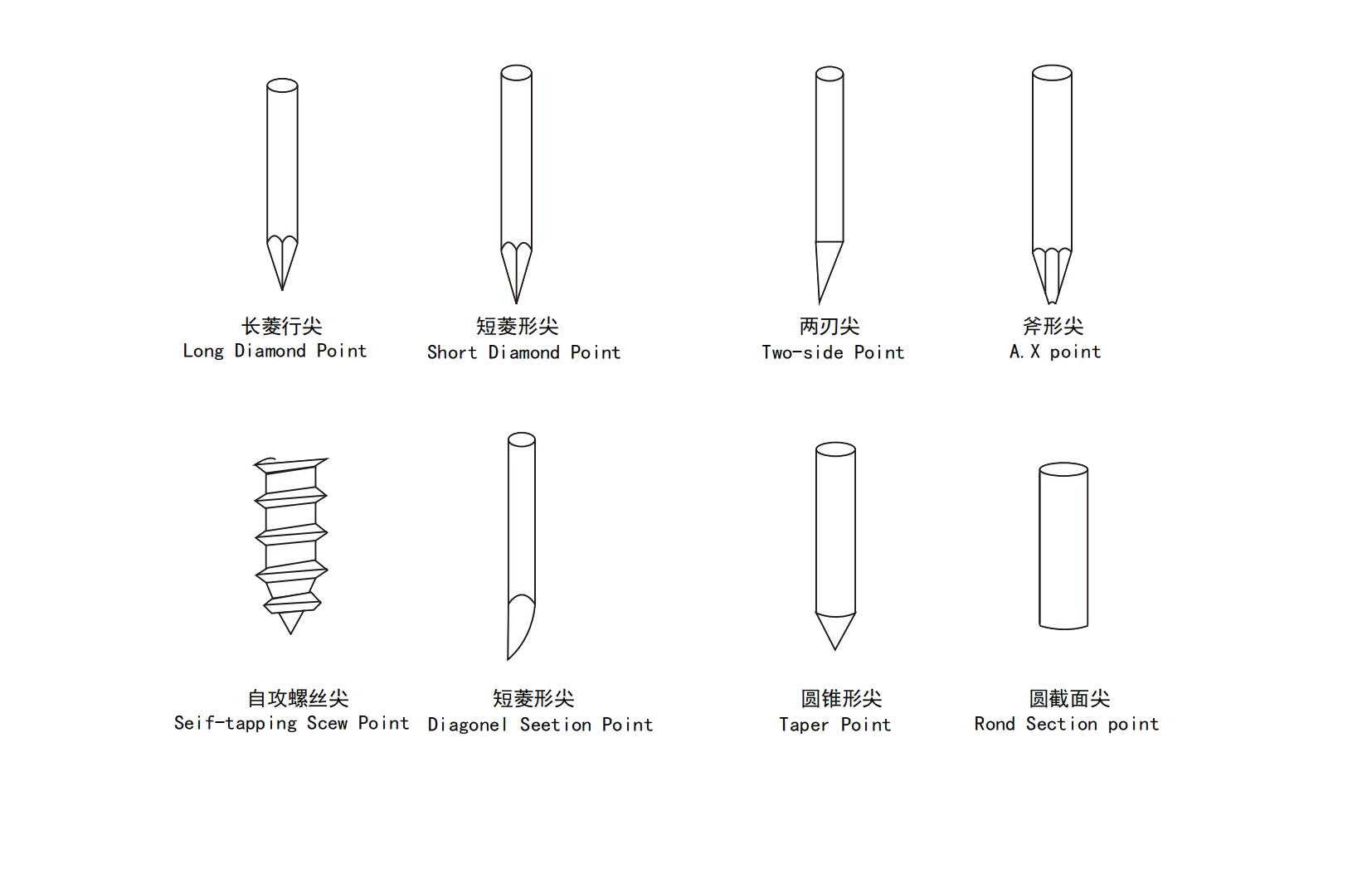

Type and Shape of Nails Point