Brad Head Nails Galvanized Nails

Application

Brad nails are incredibly versatile and can be used in various applications as they create a secure bond for your materials. They are widely used in woodworking, trim work, cabinetry, and paneling, in which appearance is a crucial factor. Their small size allows them to be used in tight spaces and corners, making them ideal for intricate pieces of furniture or architectural designs. They are also commonly used in molding applications, where a nail head is unwelcome.

Brad nails are a versatile and reliable fastener suitable for various woodworking applications, including trim work, cabinetry, and paneling. Their small size and flush head make them ideal for creating a seamless finish on your projects. Their compatibility with pneumatic nail guns and their resistance to bending, splitting, and rusting make them a popular choice among construction and renovation professionals. Choose brad nails, and you'll find that they are an indispensable tool to have in your workshop's inventory

Feature

The key features of brad nails are what make them stand out from other types of fasteners. Firstly, their small gauge and length make them ideal for delicate woodworking projects, where a power tool is necessary. They are compatible with pneumatic nail guns, which can fire several nails in rapid succession, saving time and effort. Secondly, the nails' design is perfect for hiding unsightly nail holes as they have a small head that sits flush with the surface. This feature makes them ideal for trim work and cabinetry, where the appearance is critical. Lastly, the nails are made from durable and high-quality materials, making them resistant to bending, splitting, and rusting that ensures their longevity.

Material Constituents for Common Wire Nails

|

Sus |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

|

304 |

0.08 |

1.00 |

2.00 |

0.045 |

0.027 |

8.0-10.5 |

18.0-20.0 |

0.75 |

0.75 |

|

304Hc |

0.08 |

1.00 |

2.00 |

0.045 |

0.028 |

8.5-10.5 |

17.0-19.0 |

|

2.0-3.0 |

|

316 |

0.08 |

1.00 |

2.00 |

0.045 |

0.029 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

0.75 |

|

430 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

|

16.0-18.0 |

|

Wire Brands for Different Country

|

mm |

CN.W.G |

S.W.G |

B.W.G |

AS.W.G |

|

1G |

|

|

7.52 |

7.19 |

|

2G |

|

|

7.21 |

6.67 |

|

3G |

|

|

6.58 |

6.19 |

|

4G |

|

|

6.05 |

5.72 |

|

5G |

|

|

5.59 |

5.26 |

|

6G |

5.00 |

4.88 |

5.16 |

4.88 |

|

7G |

4.50 |

4.47 |

4.57 |

4.50 |

|

8G |

4.10 |

4.06 |

4.19 |

4.12 |

|

9G |

3.70 |

3.66 |

3.76 |

3.77 |

|

10G |

3.40 |

3.25 |

3.40 |

3.43 |

|

11G |

3.10 |

2.95 |

2.05 |

3.06 |

|

12G |

2.80 |

2.64 |

2.77 |

2.68 |

|

13G |

2.50 |

2.34 |

2.41 |

2.32 |

|

14G |

2.00 |

2.03 |

2.11 |

2.03 |

|

15G |

1.80 |

1.83 |

1.83 |

1.83 |

|

16G |

1.60 |

1.63 |

1.65 |

1.58 |

|

17G |

1.40 |

1.42 |

1.47 |

1.37 |

|

18G |

1.20 |

1.22 |

1.25 |

1.21 |

|

19G |

1.10 |

1.02 |

1.07 |

1.04 |

|

20G |

1.00 |

0.91 |

0.89 |

0.88 |

|

21G |

0.90 |

0.81 |

0.81 |

0.81 |

|

22G |

|

0.71 |

0.71 |

0.73 |

|

23G |

|

0.61 |

0.63 |

0.66 |

|

24G |

|

0.56 |

0.56 |

0.58 |

|

25G |

|

0.51 |

0.51 |

0.52 |

Custom Design Nails

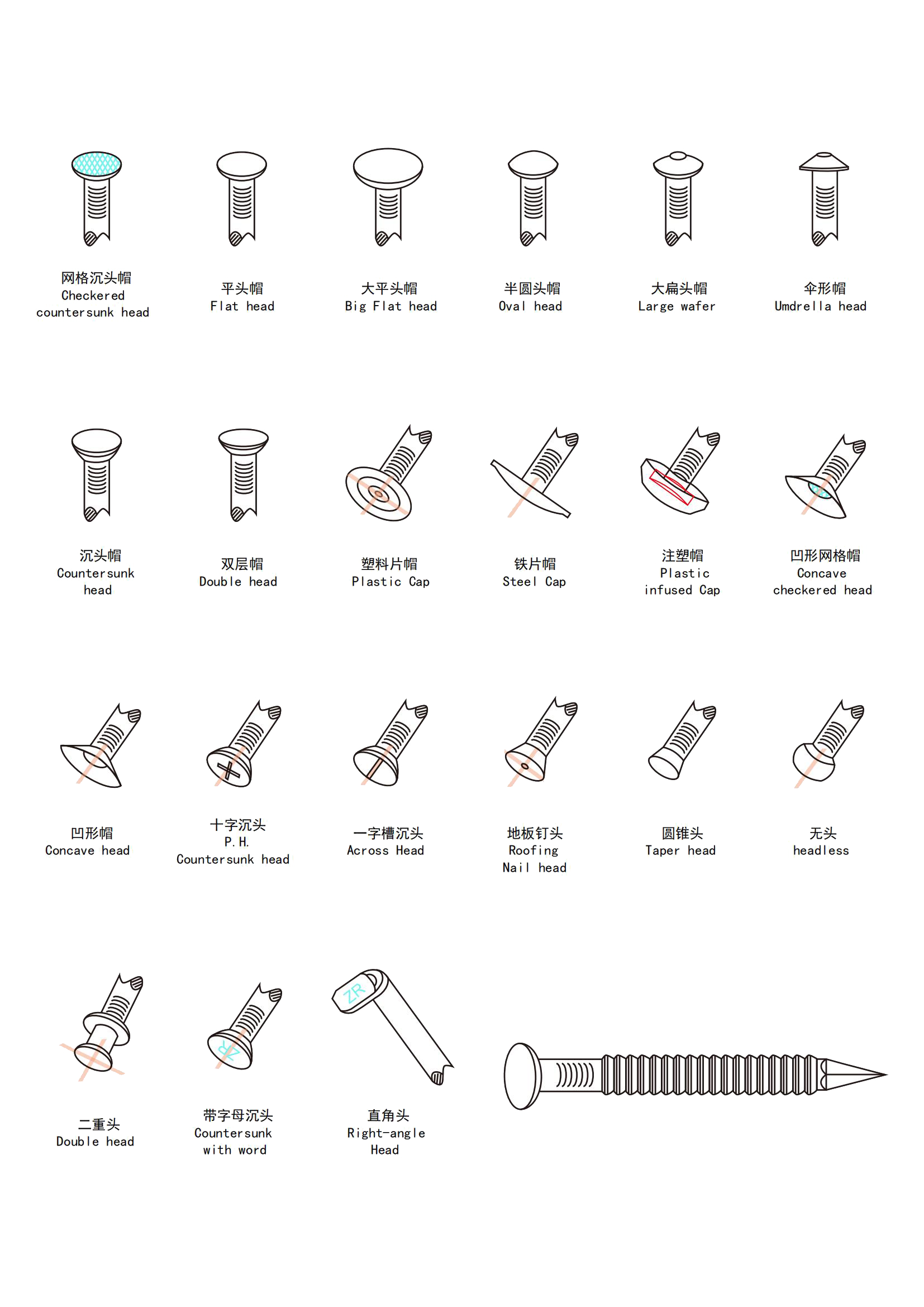

Type and Shape of Nails Head

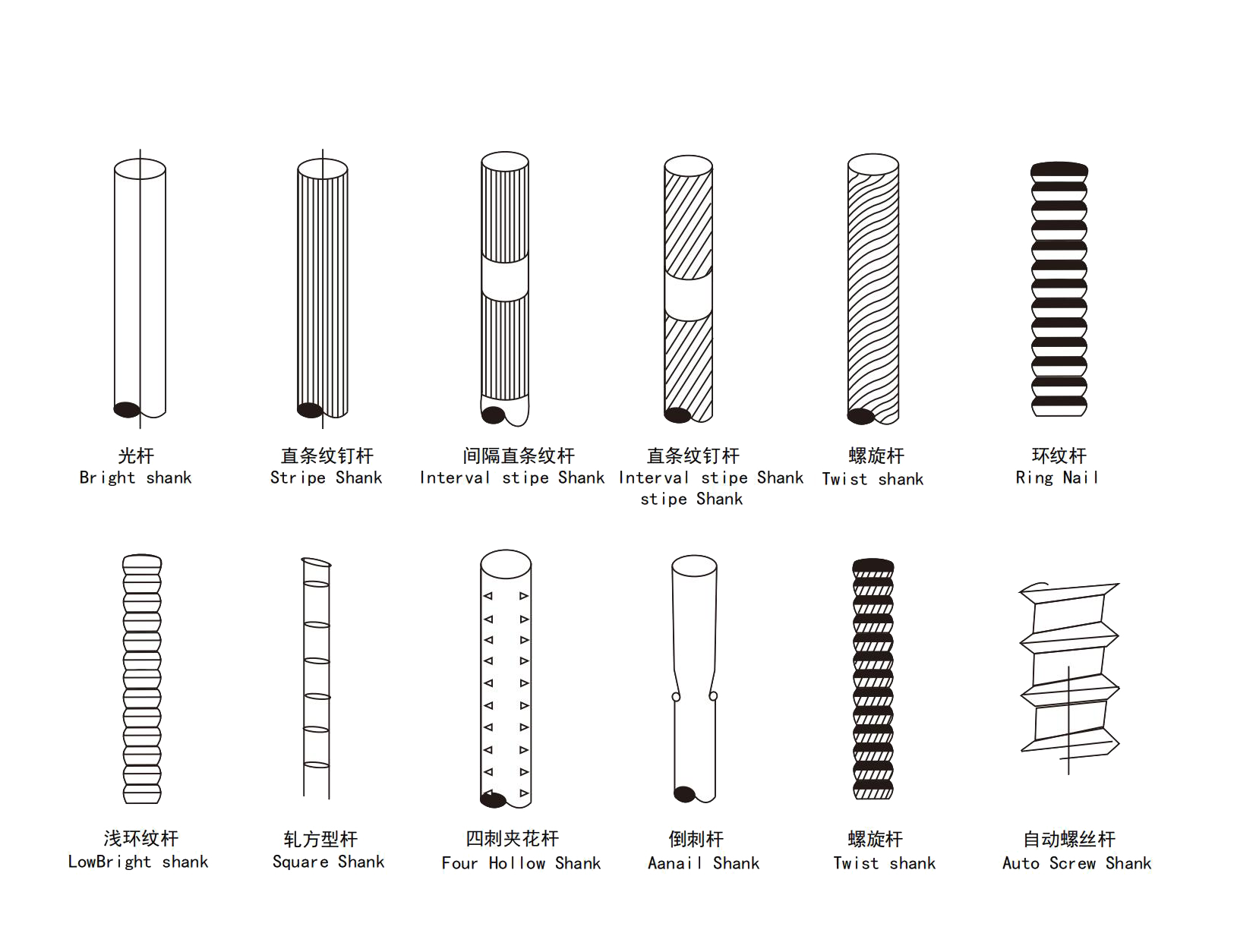

Type and Shape of Nails Shank

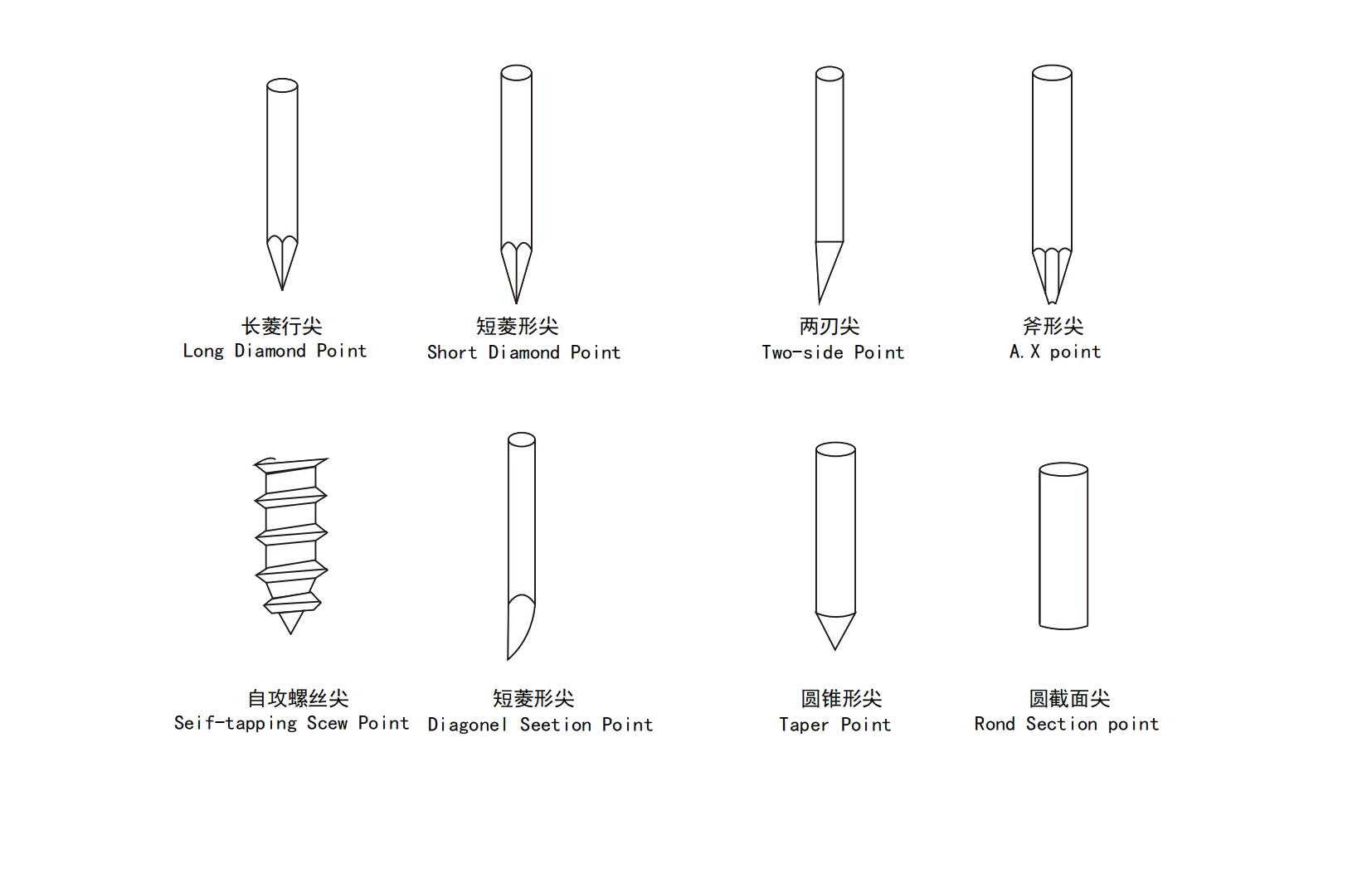

Type and Shape of Nails Point