Ring Shank Nails Anti-rust

Application

As mentioned earlier, ring shank nails are essential in construction work and are used in a variety of applications. Because of their strong holding power, they are commonly used in framing, trim and roofing. They can also be used to secure siding and trim, and to secure subfloors and sheathing.

One of the most popular applications for ring shank nails is in building wood decks. The screw shank of the nail ensures that the deck stays in place while preventing the wood from splitting. Ring shank nails are especially useful for areas that experience heavy snow, as it can hold weight without the board loosening.

Feature

Ring shank nails are designed to be more reliable and durable than other types of nails. The twist in the shank creates a strong grip, making it harder to pull the nail out, even if the wood expands or contracts due to changes in temperature or humidity. This also eliminates the need for pre-drilling, as nails can simply be driven into the wood without fear of splitting or splitting.

Another great feature of ring shank nails is that they are compatible with different types of wood. They are designed for use with both soft and hardwoods, making them a versatile choice for a variety of construction projects. This nail is also incredibly corrosion resistant, meaning it can be used in outdoor environments without compromising its strength and durability.

Material Constituents for Common Wire Nails

|

Sus |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

|

304 |

0.08 |

1.00 |

2.00 |

0.045 |

0.027 |

8.0-10.5 |

18.0-20.0 |

0.75 |

0.75 |

|

304Hc |

0.08 |

1.00 |

2.00 |

0.045 |

0.028 |

8.5-10.5 |

17.0-19.0 |

|

2.0-3.0 |

|

316 |

0.08 |

1.00 |

2.00 |

0.045 |

0.029 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

0.75 |

|

430 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

|

16.0-18.0 |

|

Wire Brands for Different Country

|

mm |

CN.W.G |

S.W.G |

B.W.G |

AS.W.G |

|

1G |

|

|

7.52 |

7.19 |

|

2G |

|

|

7.21 |

6.67 |

|

3G |

|

|

6.58 |

6.19 |

|

4G |

|

|

6.05 |

5.72 |

|

5G |

|

|

5.59 |

5.26 |

|

6G |

5.00 |

4.88 |

5.16 |

4.88 |

|

7G |

4.50 |

4.47 |

4.57 |

4.50 |

|

8G |

4.10 |

4.06 |

4.19 |

4.12 |

|

9G |

3.70 |

3.66 |

3.76 |

3.77 |

|

10G |

3.40 |

3.25 |

3.40 |

3.43 |

|

11G |

3.10 |

2.95 |

2.05 |

3.06 |

|

12G |

2.80 |

2.64 |

2.77 |

2.68 |

|

13G |

2.50 |

2.34 |

2.41 |

2.32 |

|

14G |

2.00 |

2.03 |

2.11 |

2.03 |

|

15G |

1.80 |

1.83 |

1.83 |

1.83 |

|

16G |

1.60 |

1.63 |

1.65 |

1.58 |

|

17G |

1.40 |

1.42 |

1.47 |

1.37 |

|

18G |

1.20 |

1.22 |

1.25 |

1.21 |

|

19G |

1.10 |

1.02 |

1.07 |

1.04 |

|

20G |

1.00 |

0.91 |

0.89 |

0.88 |

|

21G |

0.90 |

0.81 |

0.81 |

0.81 |

|

22G |

|

0.71 |

0.71 |

0.73 |

|

23G |

|

0.61 |

0.63 |

0.66 |

|

24G |

|

0.56 |

0.56 |

0.58 |

|

25G |

|

0.51 |

0.51 |

0.52 |

Custom Design Nails

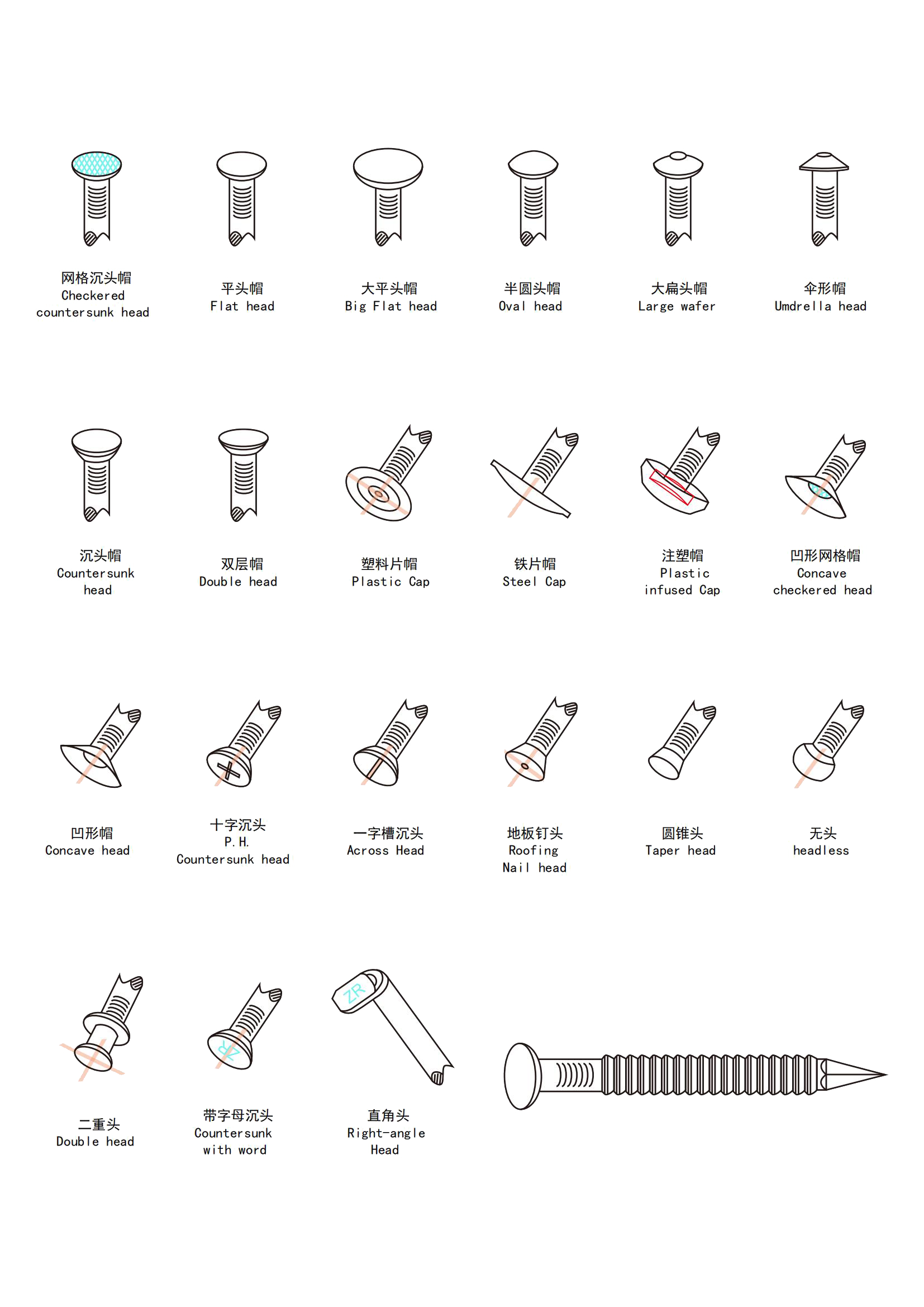

Type and Shape of Nails Head

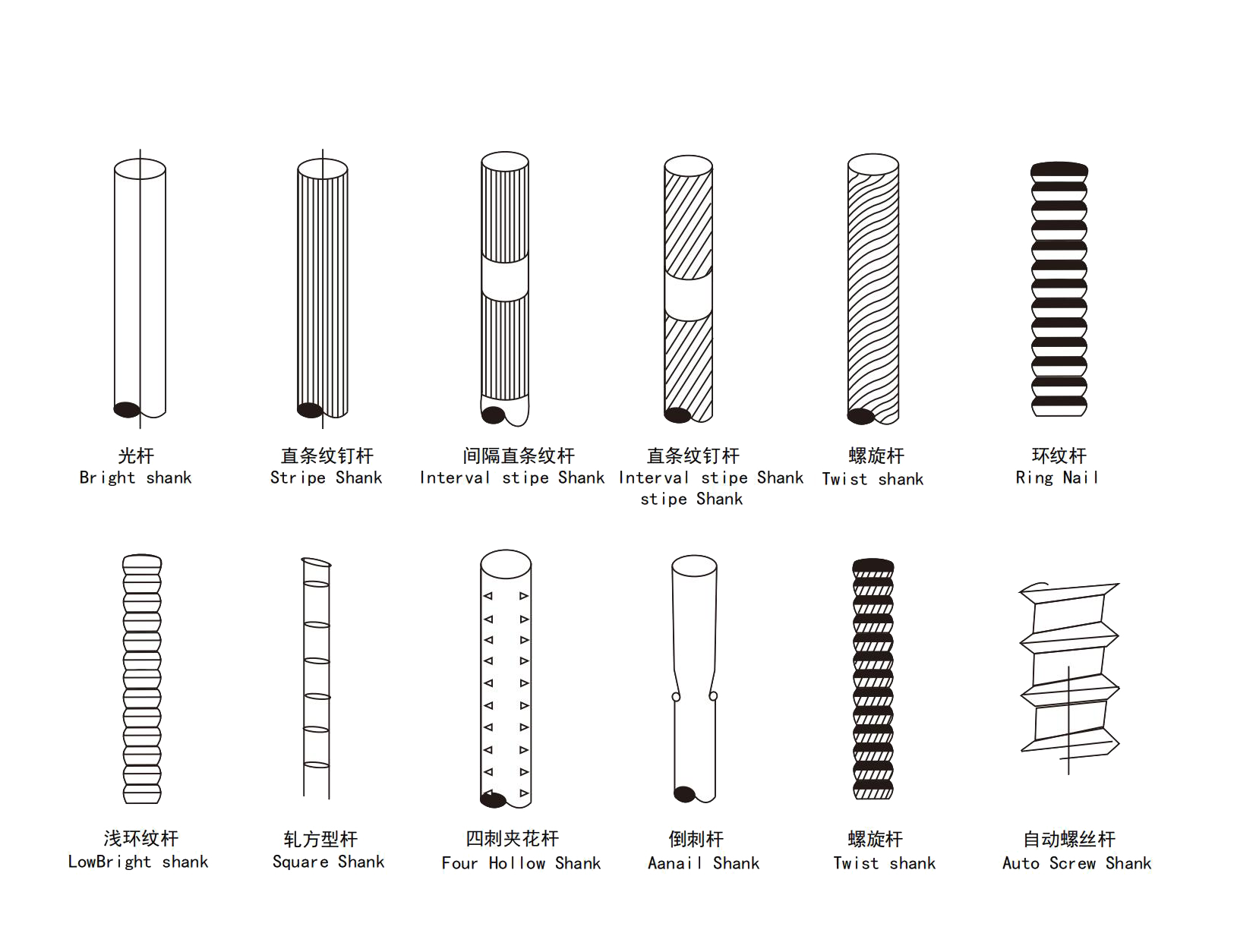

Type and Shape of Nails Shank

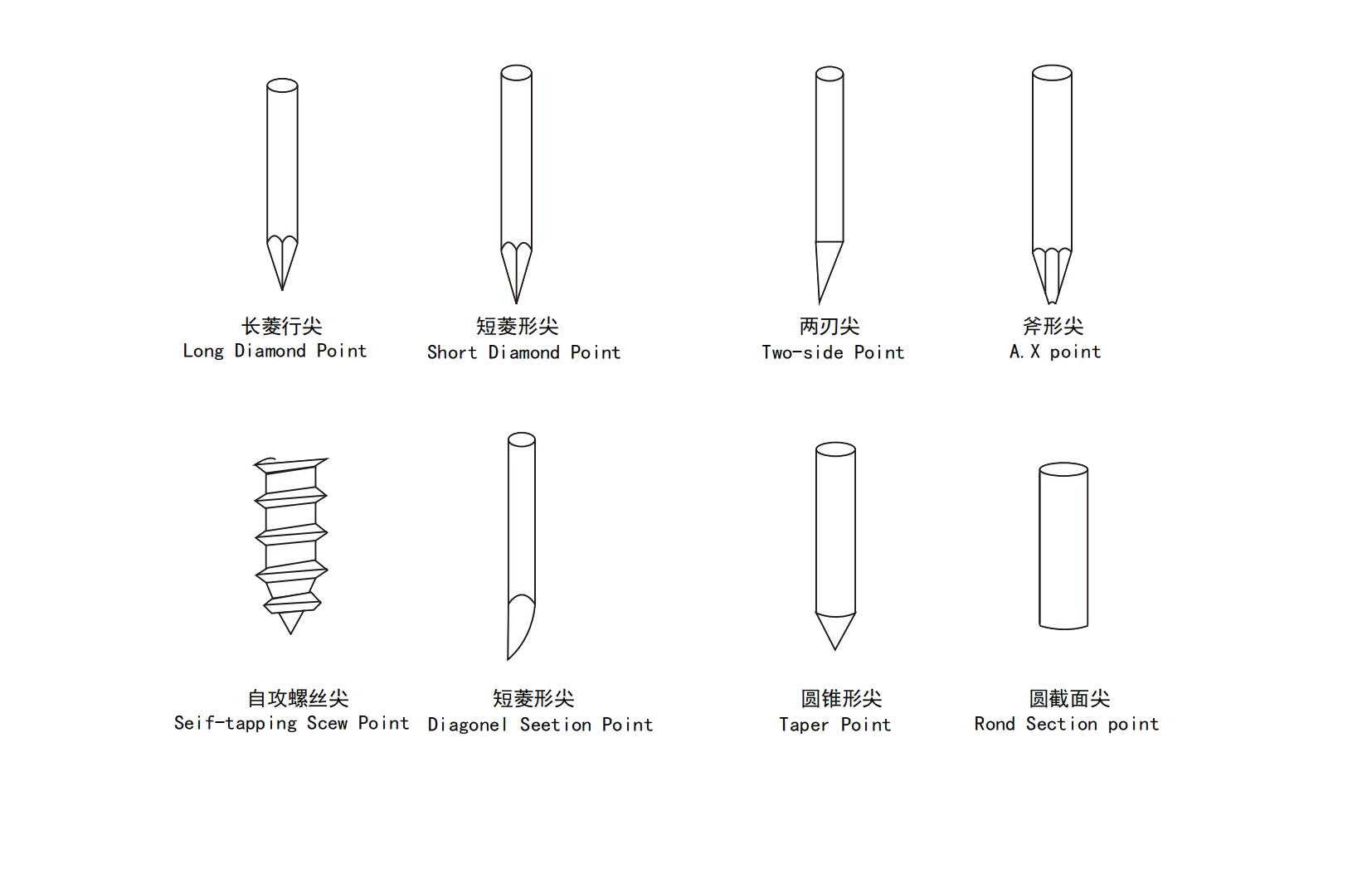

Type and Shape of Nails Point