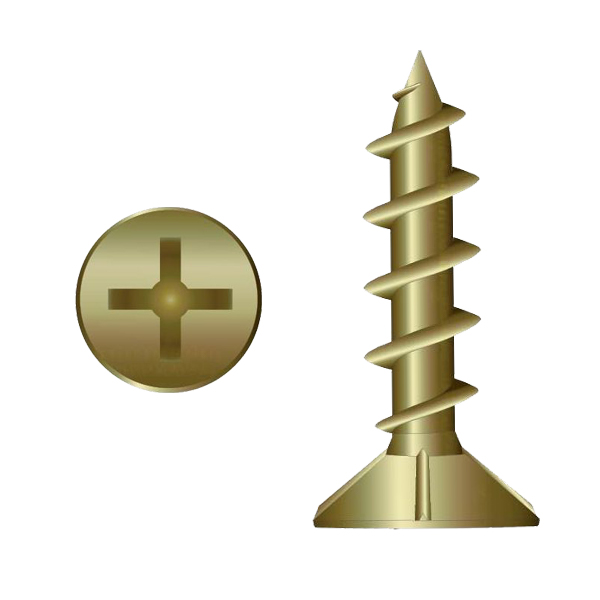

A revolutionary screw design is set to transform the way we approach woodworking projects. This innovative chipboard screw boasts a thin core diameter and a sharp angle of the thread, making it suitable for use in chipboard and soft wood types without the need for predrilling. This not only enhances convenience but also saves valuable production time.

Traditional screws often require predrilling in chipboard and soft wood types, resulting in frustrating delays and increased labor. However, with this new chipboard screw, the need for predrilling is eliminated, thanks to its unique design features. The thin core diameter and sharp angle of the thread allow the screw to cut into the wood effortlessly, minimizing splitting effects.

In addition to its time-saving benefits, this screw design offers another significant advantage – increased battery life on power tools. By reducing the insertion torque required, the chipboard screw puts less strain on the power tool’s battery, resulting in extended usage time. This is particularly beneficial for professionals working on extensive woodworking projects or for those using power tools for extended periods.

Furthermore, the pull-out forces of this chipboard screw are more consistent due to reduced splitting. Traditional screws have a higher risk of causing wood splitting during insertion or removal, which can compromise the overall stability of the structure. With this new design, the risk of splitting is significantly decreased, providing a stronger foundation and enhancing safety.

The development of this chipboard screw aligns with the guidelines recommended by popular search engines such as Google for better search engine optimization. Its content selection and writing style follow the rules for enhanced visibility and accessibility.

Woodworkers can now rejoice in this breakthrough technology that simplifies their work process and maximizes efficiency. The benefits of using this chipboard screw in both chipboard and soft wood types unquestionably outweigh the traditional drilling and screwing methods.

In conclusion, the chipboard screw with its thin core diameter, sharp angle of the thread, and enhanced pull-out forces offers significant advantages to woodworkers. Not only does it eliminate the need for predrilling in softer woods, but it also increases battery life on power tools and saves precious production time. This cutting-edge screw design is undoubtedly a game-changer in the woodworking industry, providing professionals and enthusiasts with a reliable, efficient, and time-saving solution.

Post time: Jul-28-2023