Ring Shank Pallet Coil Nails

Application

Ring shank pallet coil nails find extensive application in multiple industries, primarily within construction and woodworking. Ideal for fastening pallets, crates, roofing materials, subfloors, and other structural components, these nails offer unparalleled grip and strength. The ring shank design prevents the nails from loosening or backing out, ensuring the long-lasting integrity of the fastened materials. Whether you are building a deck, installing a subfloor, or constructing a wooden frame, ring shank pallet coil nails are a reliable choice to secure your project with confidence.

Feature

1. Superior Holding Power: Thanks to their ring shank texture, these nails provide outstanding holding power, surpassing that of smooth-shank nails. The rings effectively grip the wood fibers, minimizing the chances of withdrawal and creating a sturdy connection.

2. Durability: Manufactured from high-quality steel, ring shank pallet coil nails are highly durable and resistant to bending or twisting. This durability ensures that the nails can withstand heavy loads and harsh elements without compromising their performance.

3. Efficient Loading: The coil shape of these nails allows for efficient loading into nail guns. This eliminates the need for frequent reloading, saving time and increasing productivity during fastening operations.

4. Versatility: Ring shank pallet coil nails are available in various lengths and gauges, catering to different applications and materials. This versatility ensures that there is an appropriate size for every specific requirement, allowing for optimal fastening results.

Material Constituents

|

Sus |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

|

304 |

0.08 |

1.00 |

2.00 |

0.045 |

0.027 |

8.0-10.5 |

18.0-20.0 |

0.75 |

0.75 |

|

304Hc |

0.08 |

1.00 |

2.00 |

0.045 |

0.028 |

8.5-10.5 |

17.0-19.0 |

|

2.0-3.0 |

|

316 |

0.08 |

1.00 |

2.00 |

0.045 |

0.029 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

0.75 |

|

430 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

|

16.0-18.0 |

|

Wire Brands for Different Country

|

mm |

CN.W.G |

S.W.G |

B.W.G |

AS.W.G |

|

1G |

|

|

7.52 |

7.19 |

|

2G |

|

|

7.21 |

6.67 |

|

3G |

|

|

6.58 |

6.19 |

|

4G |

|

|

6.05 |

5.72 |

|

5G |

|

|

5.59 |

5.26 |

|

6G |

5.00 |

4.88 |

5.16 |

4.88 |

|

7G |

4.50 |

4.47 |

4.57 |

4.50 |

|

8G |

4.10 |

4.06 |

4.19 |

4.12 |

|

9G |

3.70 |

3.66 |

3.76 |

3.77 |

|

10G |

3.40 |

3.25 |

3.40 |

3.43 |

|

11G |

3.10 |

2.95 |

2.05 |

3.06 |

|

12G |

2.80 |

2.64 |

2.77 |

2.68 |

|

13G |

2.50 |

2.34 |

2.41 |

2.32 |

|

14G |

2.00 |

2.03 |

2.11 |

2.03 |

|

15G |

1.80 |

1.83 |

1.83 |

1.83 |

|

16G |

1.60 |

1.63 |

1.65 |

1.58 |

|

17G |

1.40 |

1.42 |

1.47 |

1.37 |

|

18G |

1.20 |

1.22 |

1.25 |

1.21 |

|

19G |

1.10 |

1.02 |

1.07 |

1.04 |

|

20G |

1.00 |

0.91 |

0.89 |

0.88 |

|

21G |

0.90 |

0.81 |

0.81 |

0.81 |

|

22G |

|

0.71 |

0.71 |

0.73 |

|

23G |

|

0.61 |

0.63 |

0.66 |

|

24G |

|

0.56 |

0.56 |

0.58 |

|

25G |

|

0.51 |

0.51 |

0.52 |

Custom Design Nails

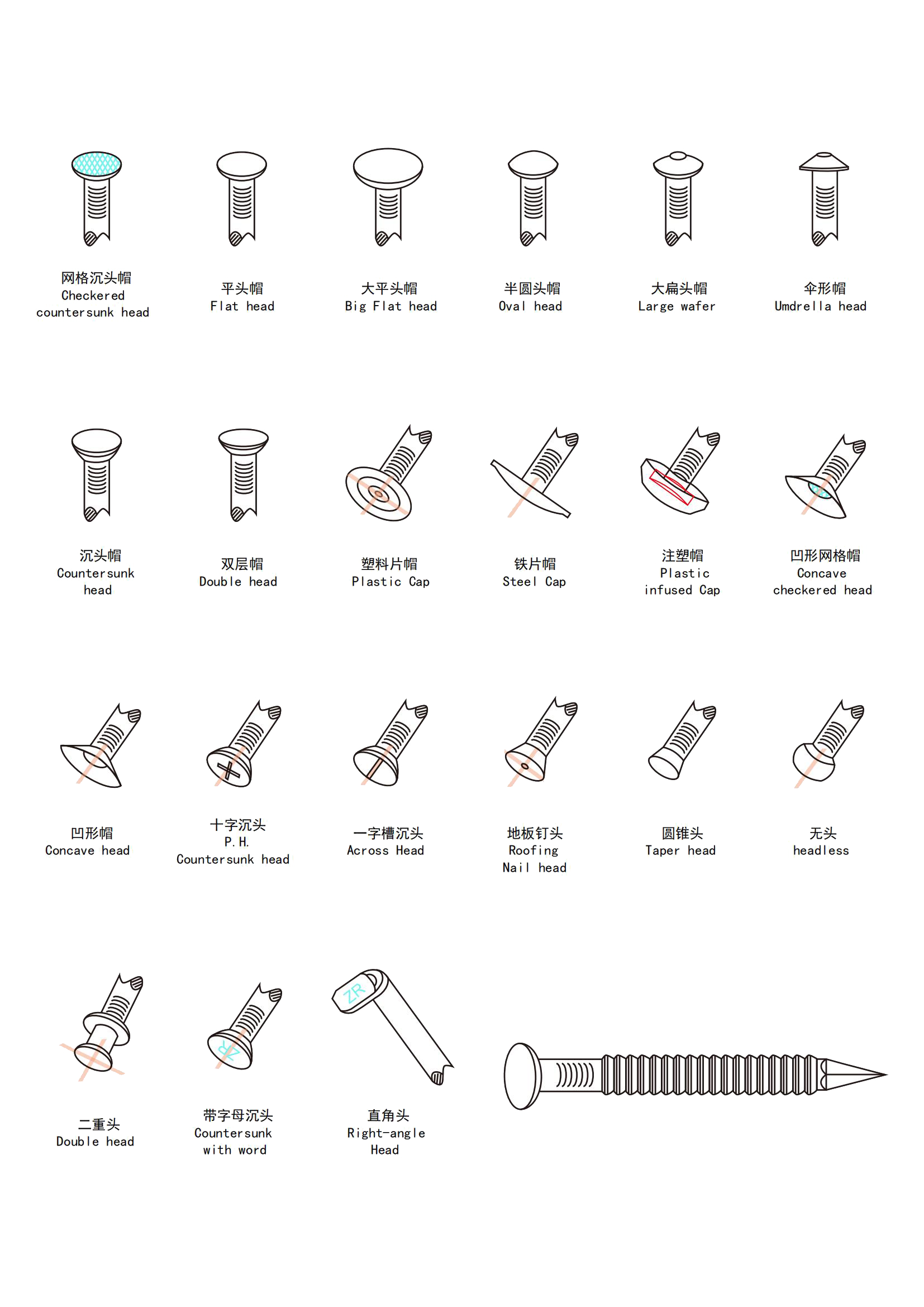

Type and Shape of Nails Head

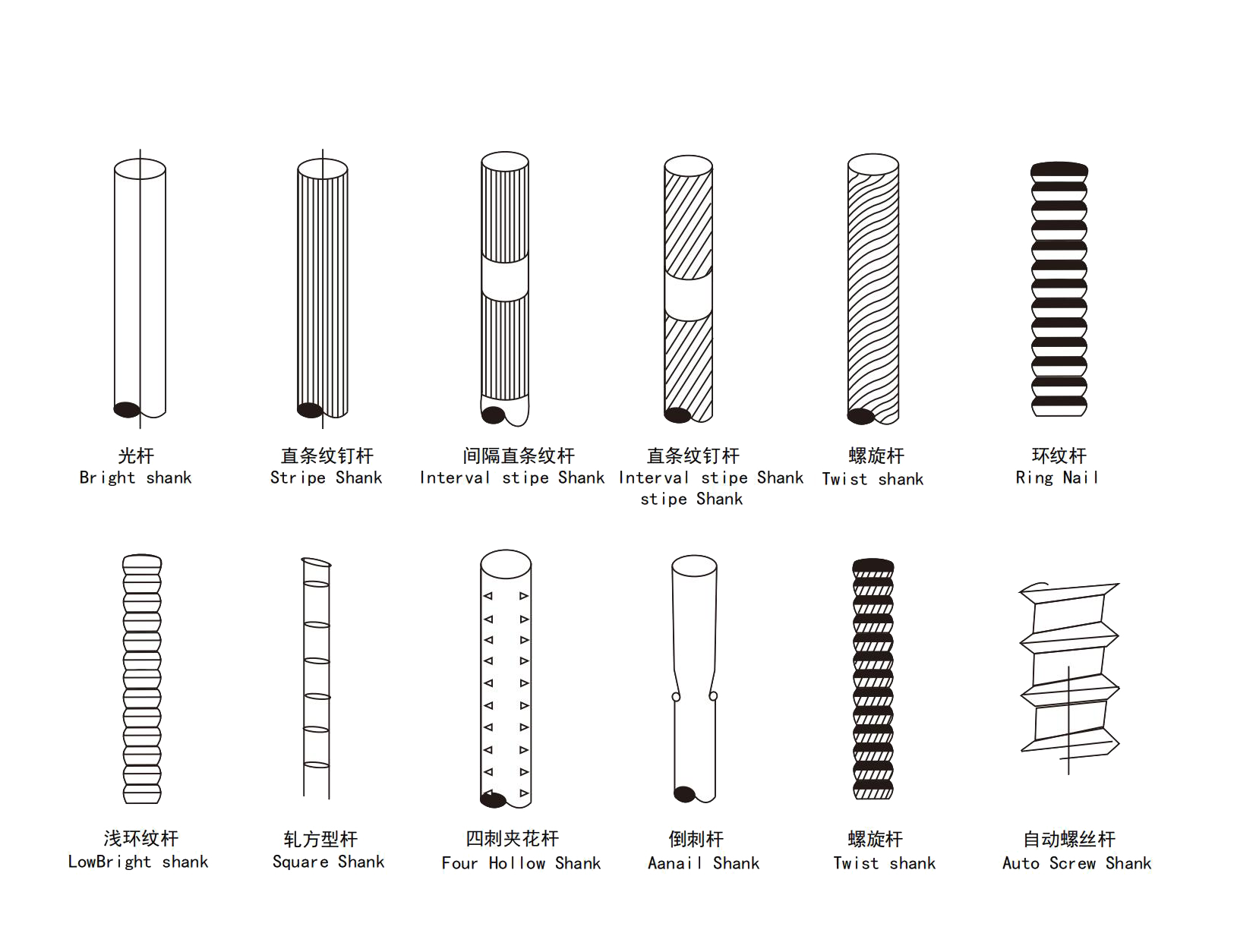

Type and Shape of Nails Shank

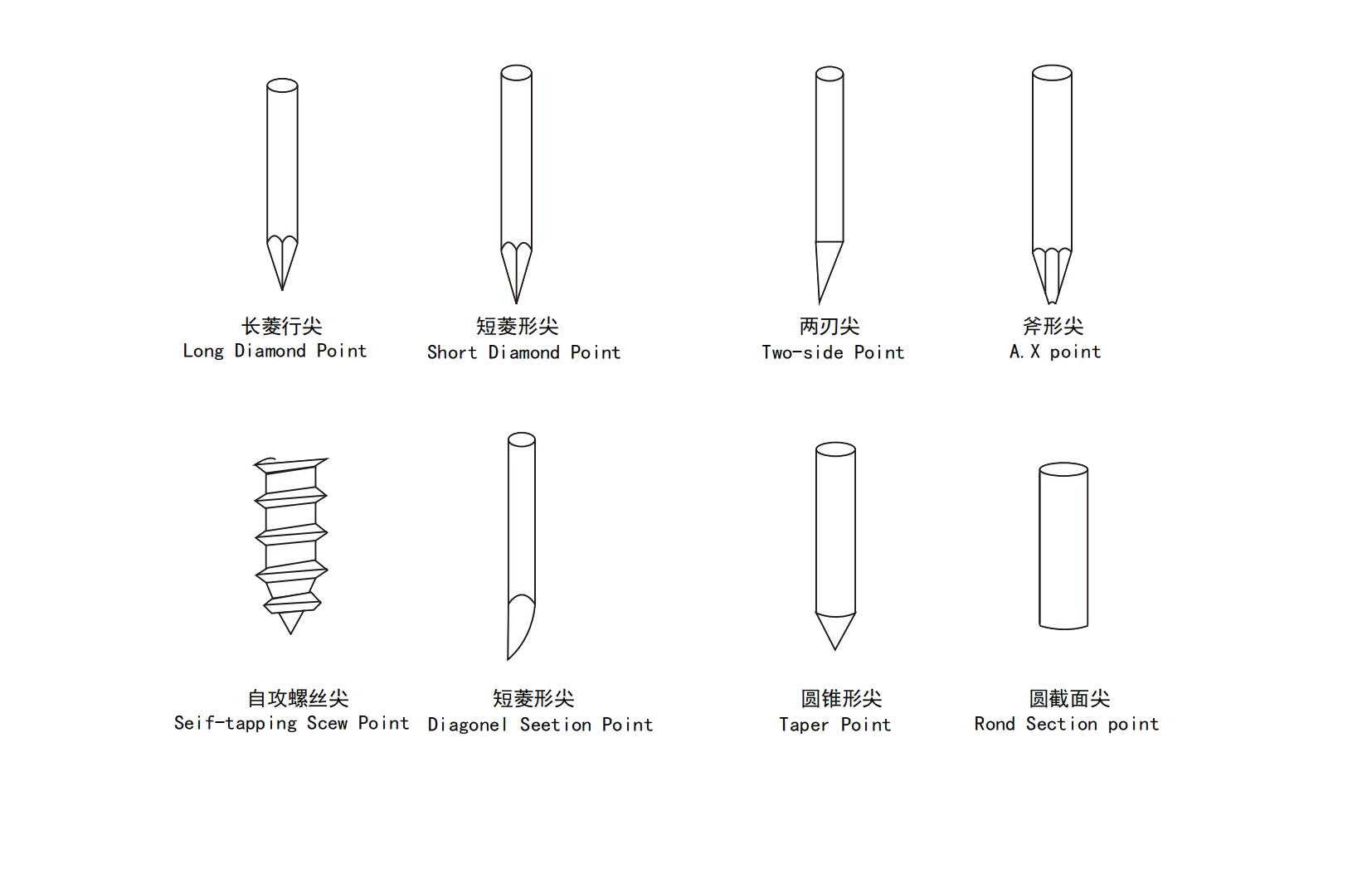

Type and Shape of Nails Point

Yihe Enterprise is a company specializing in the design and manufacture of nails, square nails, nails roll, all kinds of special shaped nails and screws. Nails material selection of quality carbon steel, copper, aluminum and stainless steel, and can do galvanized, hot dip, black, copper and other surface treatment according to customer demand. Screw main to produce US-made Machine screws ANSI, BS machine screw, bolt corrugated, including 2BA, 3BA, 4BA; German-made machine screws DIN (DIN84/ DIN963/ DIN7985/ DIN966/ DIN964/ DIN967); GB Series and other types of standard and non-standard products such as machine screws and all kinds of brass machine screws.

Our Product can be used in office furniture, ship industry ,railway , construction , automobile industry .With wide-ranging applications suitable for diverse sectors, our product stands out for its exceptional quality—crafted with premium materials and advanced production techniques to guarantee durability and optimal functionality. What’s more, we keep ample stock at all times, so you can enjoy quick delivery and avoid delays in your projects or business operations, no matter the order quantity.

Our manufacturing process is defined by superb craftsmanship—backed by advanced technology and skilled artisans, we refine every production step to ensure precision and excellence in every product. We enforce stringent quality control protocols that leave no room for compromise: raw materials are rigorously screened, production parameters are closely monitored, and final products undergo comprehensive quality assessments. Driven by a dedication to excellence, we strive to craft premium products that stand out in the market for their superior quality and long-lasting value.