Bugle Head Phillips Drywall Screws

Application

The screws’ bugle heads make drywall installation easier, especially when used for ceilings or high walls. Other benefits of this screw type include less damage to the drywall paper’s coating and protection from accidental punctures from screw guns. They are suitable for use in the construction of partition walls, ceilings, and home interiors. If you’re working on moisture-prone surfaces, it’s recommended to use screws made of stainless steel, which have anti-rust features.

Feature

Bugle head drywall screws share a variety of features that make them ideal for drywall projects. One feature is their threading, which makes the installation process faster and more secure. The flat head design reduces the chances of causing damage to the wall, making them an optimal choice for beginners in the DIY/home repair projects. These screws have excellent grip due to their threading and taper to prevent over-drilling. Lastly, they offer durability and longevity, making them an overall cost-effective choice for affordable maintenance of interior walls and ceilings.

Plating

PL: PLAIN

YZ: YELLOW ZINC

ZN: ZINC

KP: BLACK PHOSPHATED

BP: GREY PHOSPHATED

BZ: BLACK ZINC

BO: BLACK OXIDE

DC: DACROTIZED

RS: RUSPERT

XY: XYLAN

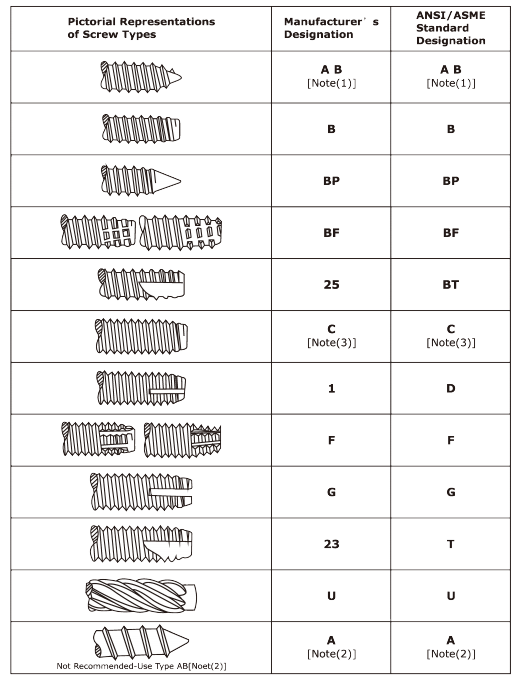

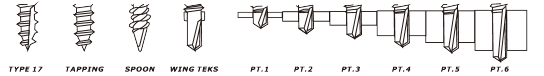

Pictorial Representations of Screw Types

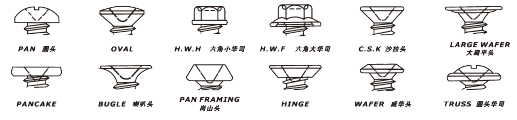

Head Styles

Head Recess

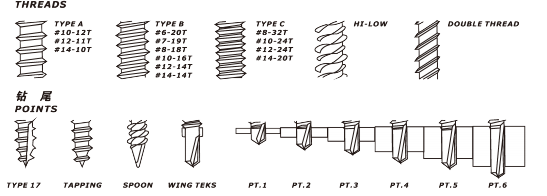

Threads

Points

Yihe Enterprise is a company specializing in the design and manufacture of nails, square nails, nails roll, all kinds of special shaped nails and screws. Nails material selection of quality carbon steel, copper, aluminum and stainless steel, and can do galvanized, hot dip, black, copper and other surface treatment according to customer demand. Screw main to produce US-made Machine screws ANSI, BS machine screw, bolt corrugated, including 2BA, 3BA, 4BA; German-made machine screws DIN (DIN84/ DIN963/ DIN7985/ DIN966/ DIN964/ DIN967); GB Series and other types of standard and non-standard products such as machine screws and all kinds of brass machine screws.

Our Product can be used in office furniture, ship industry ,railway , construction , automobile industry .With wide-ranging applications suitable for diverse sectors, our product stands out for its exceptional quality—crafted with premium materials and advanced production techniques to guarantee durability and optimal functionality. What’s more, we keep ample stock at all times, so you can enjoy quick delivery and avoid delays in your projects or business operations, no matter the order quantity.

Our manufacturing process is defined by superb craftsmanship—backed by advanced technology and skilled artisans, we refine every production step to ensure precision and excellence in every product. We enforce stringent quality control protocols that leave no room for compromise: raw materials are rigorously screened, production parameters are closely monitored, and final products undergo comprehensive quality assessments. Driven by a dedication to excellence, we strive to craft premium products that stand out in the market for their superior quality and long-lasting value.